Project implementation: Brazil

Project development: Brazil

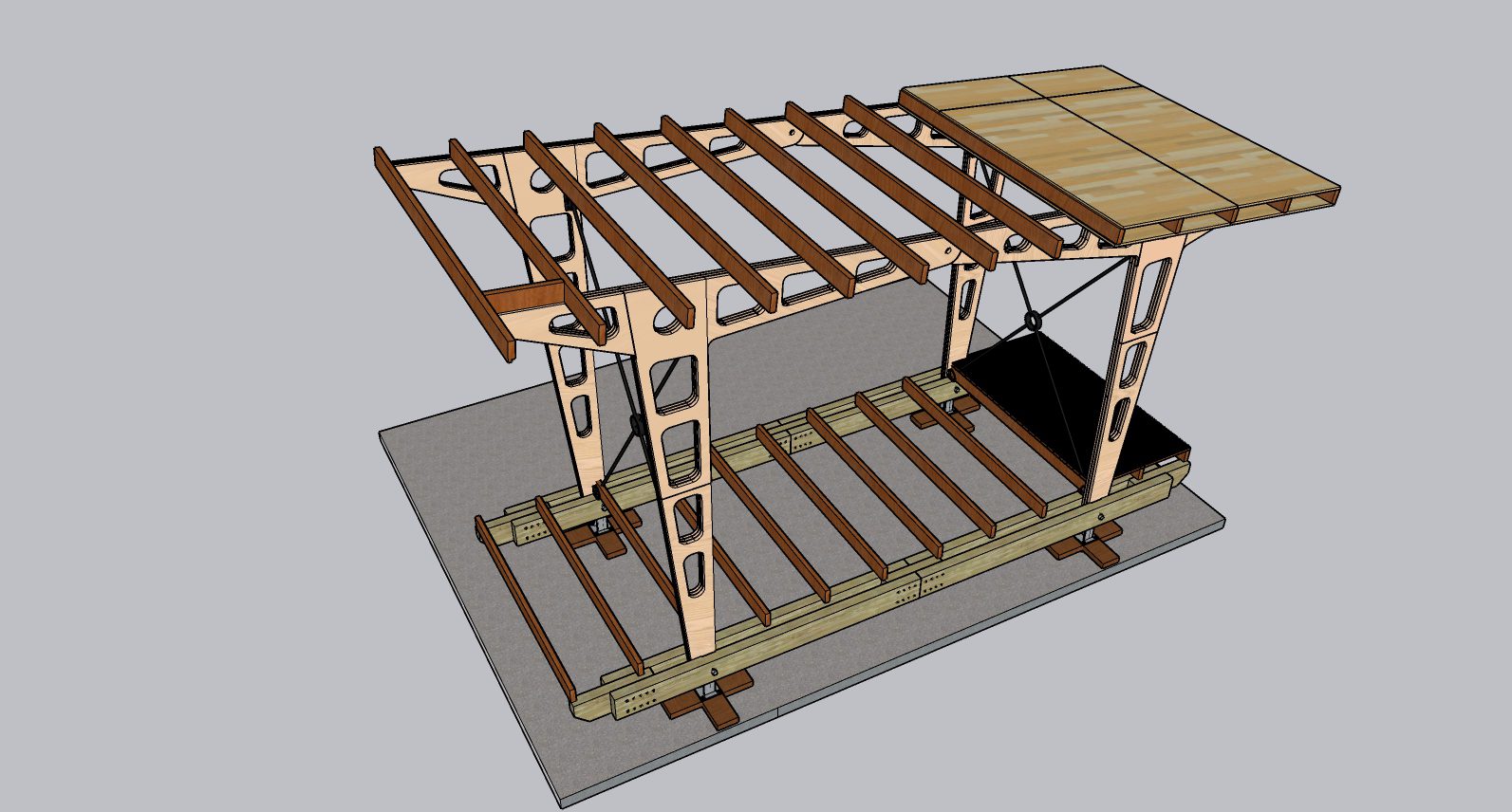

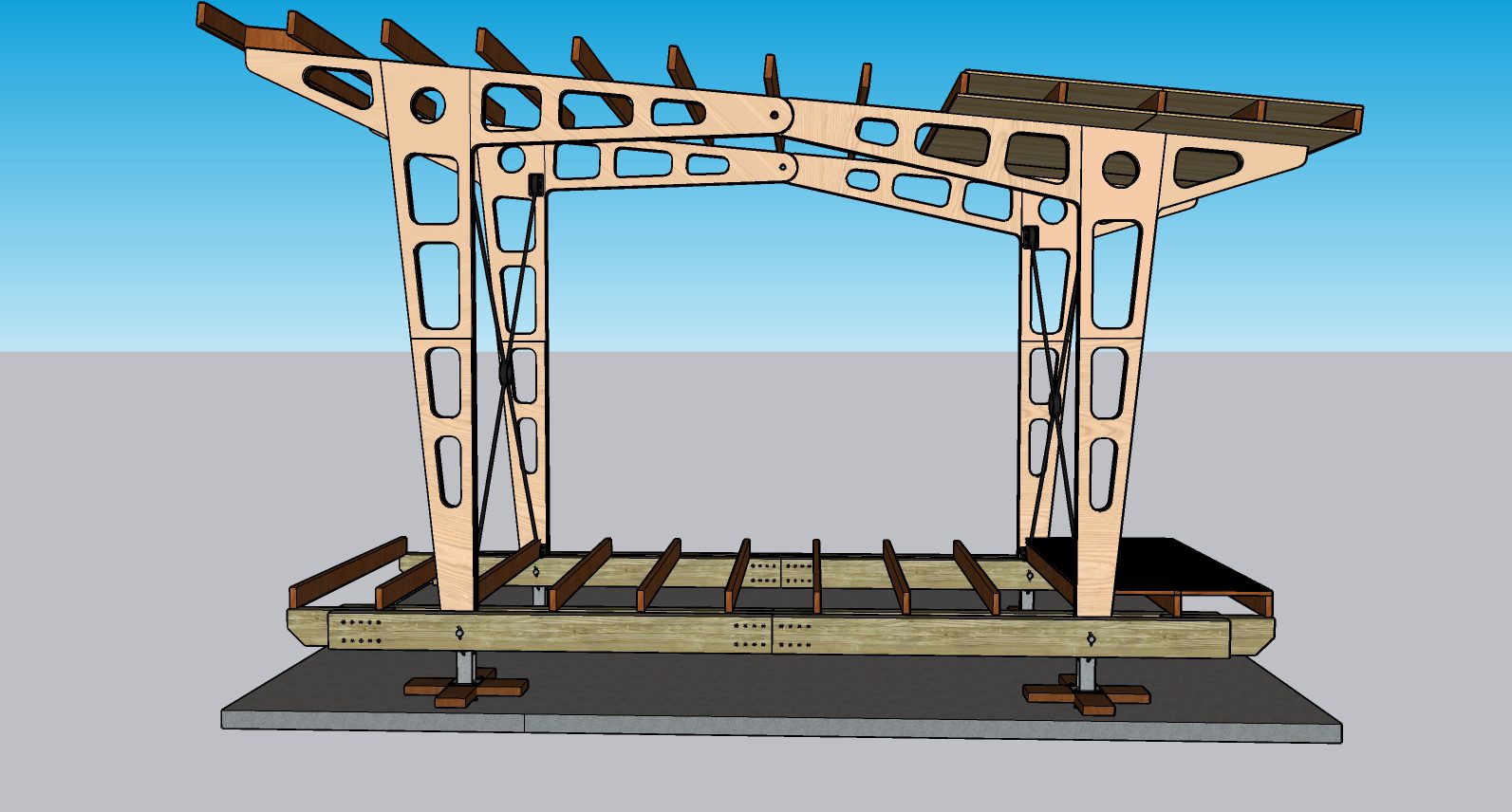

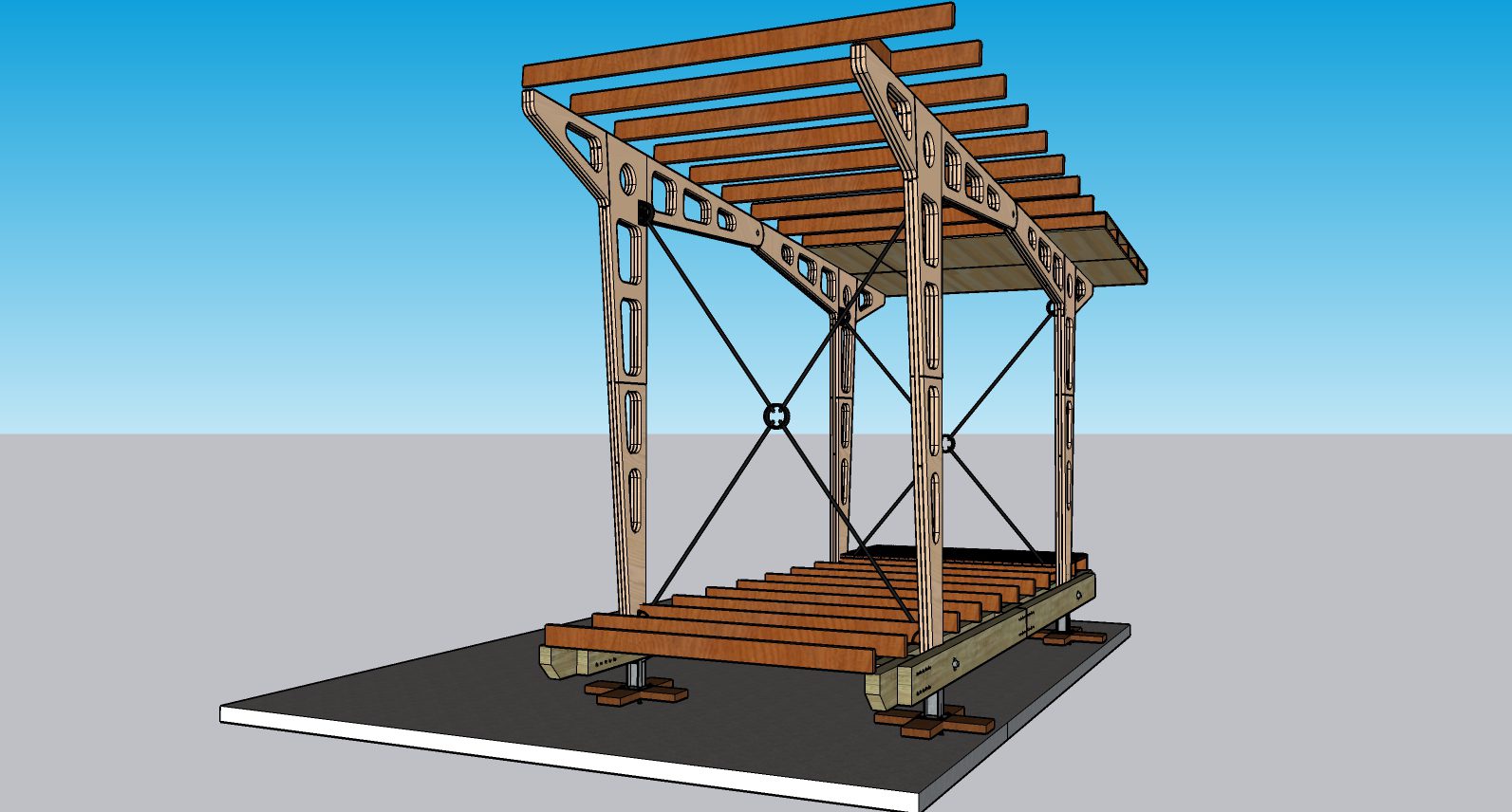

The first class of the Wood Center's Postgraduate Program, in partnership with IPT, was formed by architects, engineers, and designers interested in a pioneering proposal to expand knowledge of wood applied to Brazilian civil construction, thus seeking to address a significant gap in the training of professionals in the Brazilian market. The Integrated Project for the conclusion of the course was proposed to the students as a collective work applying the concepts discussed during the course, such as knowledge of the material and technologies, assembly logistics, geometric and aesthetic experimentation of form, dimensioning, among others, in addition to allowing students to gain real-world experience with the process and implications of design decisions. The Experimental Prototype was developed with the aim of producing a small pavilion that could be assembled from prefabricated modular wooden elements. The tri-articulated gantry is constructed from 30 mm plywood sheets, CNC-cut, glued, and bolted together to form a single pillar-and-beam assembly that supports the roof panels, manufactured using 12 x 5 cm commercial parts and 12 mm plywood sheets. The metal connection of the hot-dip galvanized steel base supports, in addition to the gantry, the floor structure, which is supported by factory-produced native wood decking panels. The assembly, designed from 2.40 m modules, allows for the gantry to be repeated and the pavilion's area to be adapted to accommodate available expansion space. The team, comprised of students and faculty, worked in the IPT carpentry shop, with the assistance of the technician in charge, to produce the prototype parts. Only the machining of the gantry panels was done externally. Understanding the complexity and difficulty of the adopted solutions and applying creativity to find viable solutions were part of the challenge of producing all the elements in a way that allowed for easy and quick assembly on site. The development of the project and the production of the prototype were supported by partner companies: Indusparquet, Rothoblaas, Immergrum, Montana Química, Osawa, Antoni Compensados, IBF, Amarante Madeiras, Formtap, Módulo Sequência, Mado Esquadrias, Omintrade.